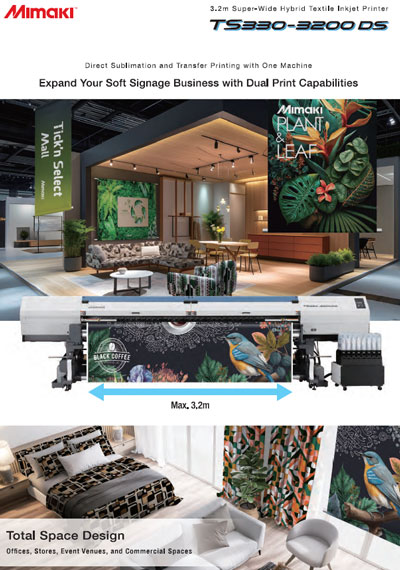

DUAL-MODE 3.2m TEXTILE PRINTER

High-speed and versatile textile printing with stunning quality

Experience the future of dye sublimation printing!

With exceptional productivity and stunning image quality, it’s perfect for high-volume operations demanding efficiency and visual impact. From vibrant banners to intricate designs, this printer delivers outstanding results.

With user-friendly features like simple maintenance and remote access, the TS330-3200DS minimises downtime and ensures your business stays ahead in the competitive textile printing industry.

Unique features

- High production speed

Achieves up to 150 sqm/h at an operational speed of 90 sqm/h, doubling productivity over previous models.Users can achieve faster production, with print speeds of up to 150 sqm/h while maintaining high-quality prints. This increased productivity and superior image quality increases efficiency and ensures impressive, close-up results for professional-grade textile printing.

Achieves up to 150 sqm/h at an operational speed of 90 sqm/h, doubling productivity over previous models.Users can achieve faster production, with print speeds of up to 150 sqm/h while maintaining high-quality prints. This increased productivity and superior image quality increases efficiency and ensures impressive, close-up results for professional-grade textile printing.

- Versatile printing mechanism

Supports both sublimation transfer paper and direct-to-fabric printing, providing versatility for various textile applications.The printer’s ability to handle both sublimation transfer paper and direct-to-fabric printing provides versatility for various applications.

Supports both sublimation transfer paper and direct-to-fabric printing, providing versatility for various textile applications.The printer’s ability to handle both sublimation transfer paper and direct-to-fabric printing provides versatility for various applications.

Users can easily switch between different printing methods using the removable platen, allowing you to work with different materials including flags, banners, and stretchy or thick fabrics.

- Superior print quality

Unique advanced imaging technologies such as Variable Dot Control and Waveform Control ensure consistent and high-quality print results.Built-in advanced imaging technology ensures high quality prints, even under close inspection, for professional results that enhance the appearance of the final product.

Unique advanced imaging technologies such as Variable Dot Control and Waveform Control ensure consistent and high-quality print results.Built-in advanced imaging technology ensures high quality prints, even under close inspection, for professional results that enhance the appearance of the final product.

- User-Friendly Design

Features an easy-to-use ink supply system, simplified maintenance, and remote access capabilities for efficient and hassle-free operation.User-friendly features such as a simplified maintenance mechanism, an easy-to-use high capacity ink supply unit, and remote access capabilities enhance convenience.

Features an easy-to-use ink supply system, simplified maintenance, and remote access capabilities for efficient and hassle-free operation.User-friendly features such as a simplified maintenance mechanism, an easy-to-use high capacity ink supply unit, and remote access capabilities enhance convenience.

Remote monitoring and control allows users to manage the printer from anywhere, reducing downtime and streamlining workflow management.

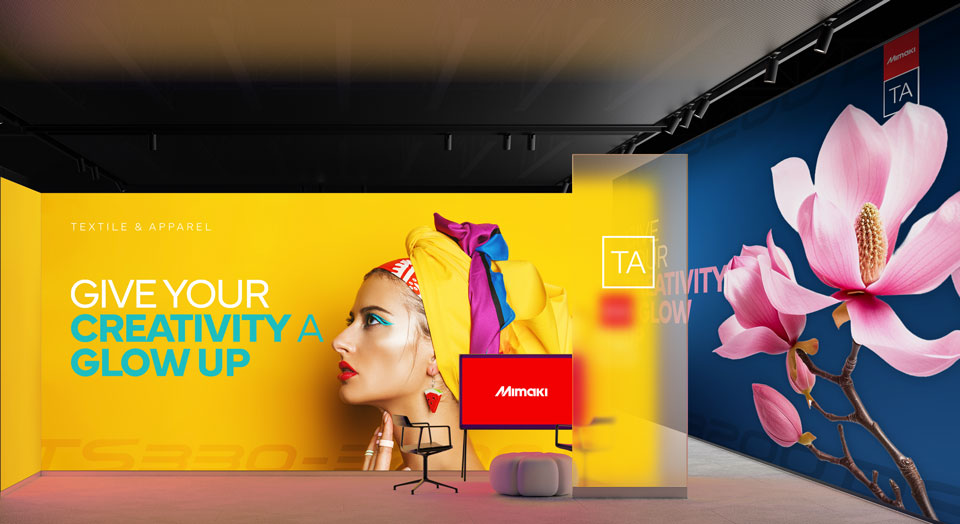

Designed to produce a wide range of textile applications

for different markets

Banners and soft signage, flags, curtains, home and interior décor, sportswear, fashion and more.

TEXTILE SIGNAGE

CORPORATE BRANDING

HOME DECOR

RETAIL DISPLAYS

TRADESHOW GRAPHICS

SPORTSWEAR & APPAREL

Versatile ink options with advanced hybrid technology

The TS330-3200DS offers versatility in textile printing with two ink options: Direct Sublimation (SB420) and Paper Transfer Sublimation (SB411). These inks allow for a wide range of applications, including sportswear, soft signage, fashion items, and home textiles, all on polyester fabrics. This flexibility ensures high-quality results for various sublimation printing needs.

For even more confidence

our inks are are bluesign® approved and OEKO-TEX® certified

Mimaki SB411 and SB420 inks are bluesign® approved and ZDHC MRSL Lv.3 certified, meeting the highest sustainability standards with minimal environmental impact and ensuring worker safety.

They are also ECO PASSPORT by OEKO-TEX® certified, confirming their suitability for skin-friendly textiles.

This printer is packed with Mimaki Core Technologies that maximises production stability and image quality at all times. Refer to the below list of core technologies that are included in the TS330-3200DS.

For continued productivity

- Nozzle Recovery System (NRS), to replace missing nozzles

- Automatic Cleaning Function, to keep the print head clean

- Uninterrupted Ink Supply System (UISS), for uninterrupted ink supply

For quality printing

- Mimaki Advanced Pass System (MAPS4), to reduce banding

- Waveform Control (WFC), for best possible image sharpness

- Variable Dots Technology (VDT), for smoother gradations

- Mimaki Fine Diffusion (MFD), for smoother colours

- Dot Adjustment System (DAS), for stable printing

| Model | TS330-3200DS |

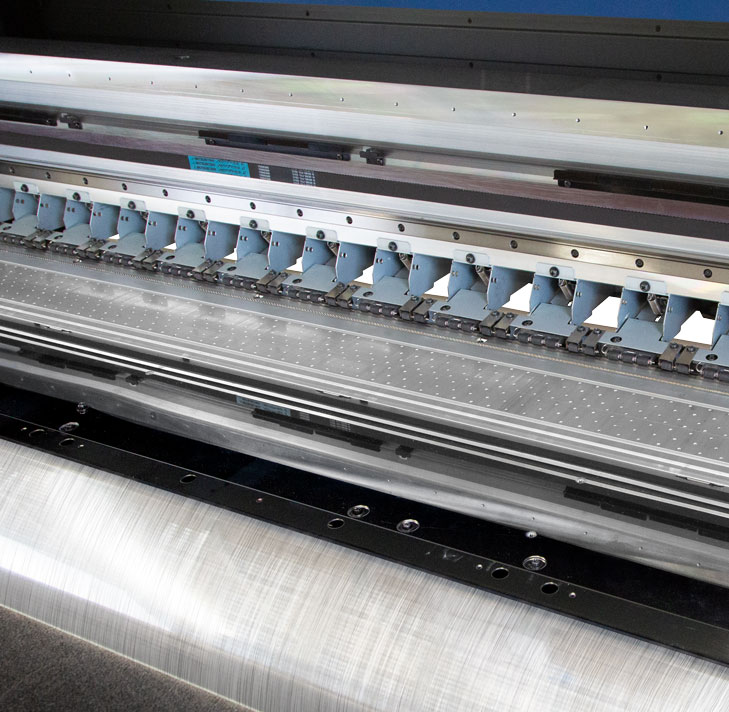

| Print head | 2 drop-on-demand piezoelectric head; stagger arrangement |

| Print resolution | Y: 300dpi, 600dpi X: 600dpi, 1200dpi |

| Drop size | Min: 4pl |

| Head height | Manual adjustment (3.0/3.5/4.0 mm from platen) |

| Compatible inks | Sb411: Bl M Y K / Sb420: Bl M Y K |

| Ink supply | 2,000ml ink bag Optional 10kg tank |

| Max printing width | 3,240mm |

| Max media width | 3,250mm |

| Media thickness | 1.0mm or less |

| Outside diameter | 250mm or less |

| Inner diameter | 2-inch / 3-inch |

| Roll weight | 100kg or less |

| Interface | USB2.0 / Ethernet 1000 BASE-T |

| Body weight | Main unit: 925 kg, external supply unit: 43 kg |

| Dimension (WxDxH) | 5,410mm / 1,075mm / 1,440mm |

| Power supply | 1 x Single phase (AC100~120/200~240V +/- 10%, 10A, 50/60Hz +/- 1Hz) |

| Power consumption | Max: 2.4kW or less |

| Safety Standards | VCCI-classA, FCC-classA, ETL compliant with IEC62368-1, CE marking (EMC Directive, Low Voltage Directive, Machinery Directive, RoHS Directive), CB certification, REACH, RCM mark, KC certification, UKCA mark |

Software RIP

The primary task of RIP (Raster Image Processor) software is to convert the different formats of the file to be printed into data that the printer “understands” as raster data.

RasterLink7

Sb411

Paper transfer sublimation ink

Sb411 produces bright and vivid colours with good light-fastness and extreme good rub- and wash-fastness. Fixation by heat with calendar or flat heat press.

Packaging

Colour

Ink type

fabrics or blended fabrics with at least 65% polyester.

Sb420

Direct sublimation ink

Produces colours with high wash-fastness and durability and excellent light-fastness for outdoor applications. Fixation by Heat with calendar or heart fixation unit.

Packaging

Colour

Ink type

More info TS330-3200DS

Request a demonstration

Brochures