TRAPIS, Revolution in Textile Printing

Eco-friendly and versatile textile printing made easy

Diverse and sustainable textile printing with TRAPIS for a greener tomorrow

TRAPIS, short for Transfer Pigment System, is a groundbreaking waterless digital textile printing technology developed by Mimaki. This waterless technology is eco-friendly, efficient, and versatile.

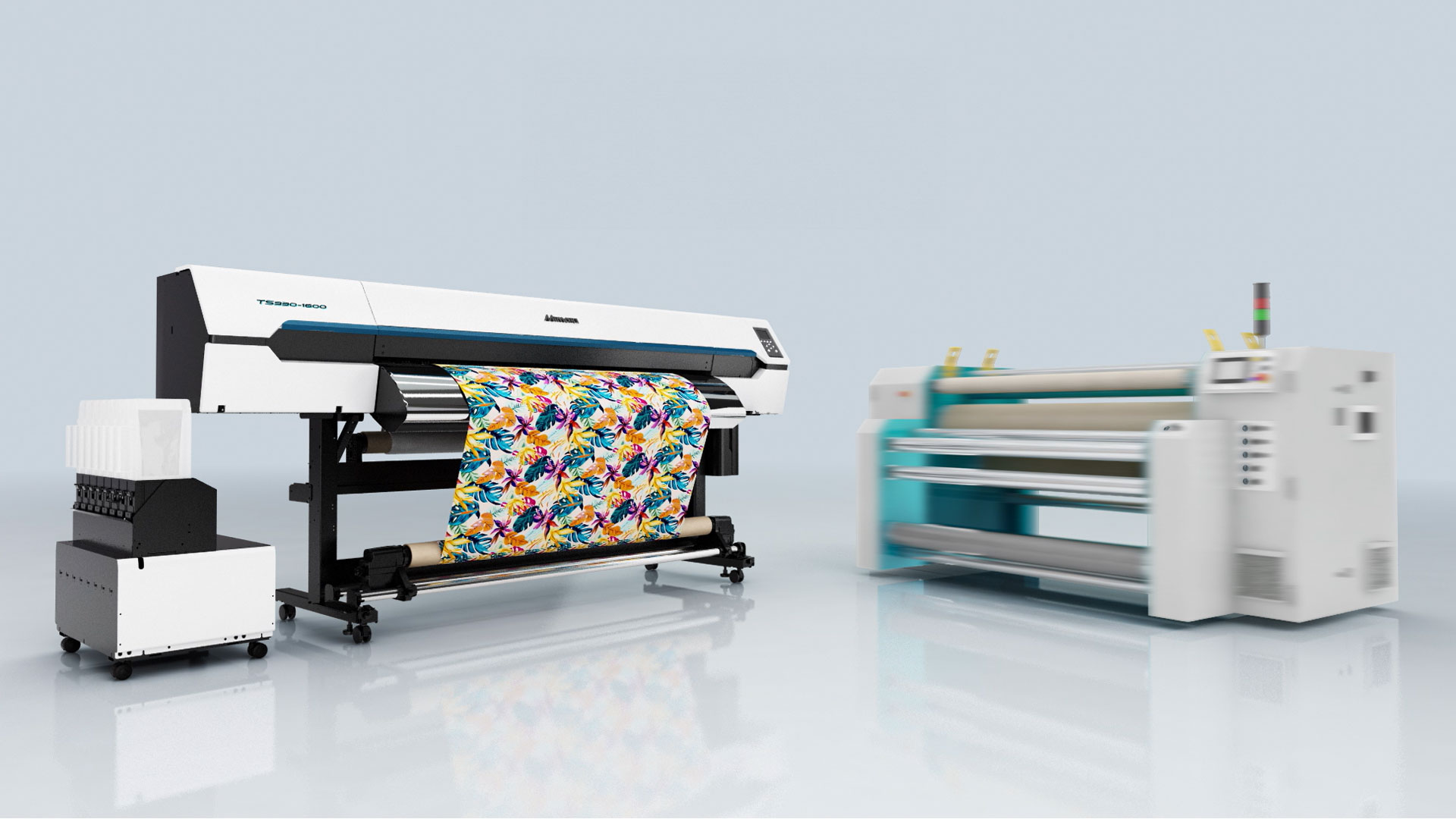

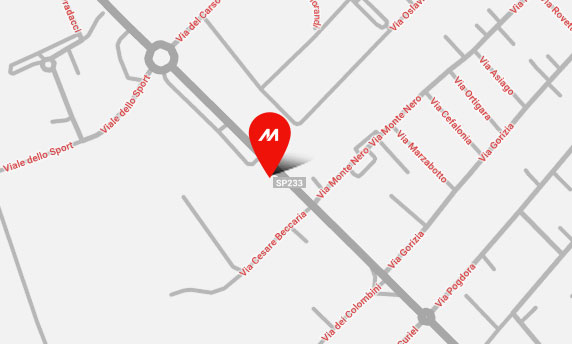

TRAPIS provides a simple two-step process, consisting of a Mimaki TS330 printer with a TP ink set, heater unit and a calender (allowing a pressure of 5-8 bar). The design of choice is printed by the TS330 onto Mimaki Texcol paper, which is then transferred to the fabric via a calender.

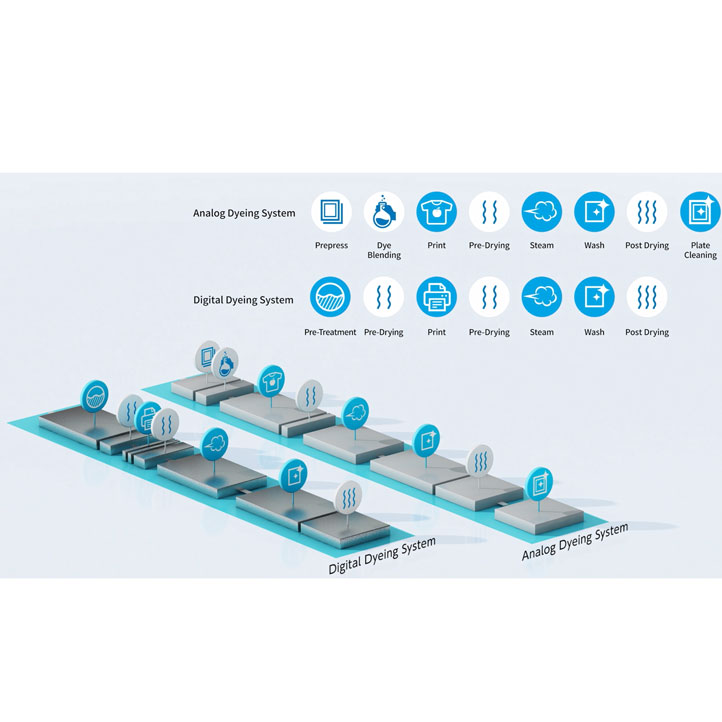

Unlike both analogue and digital conventional dye-printing methods, TRAPIS enables printing and commercialisation with virtually no water.

Diverse and sustainable textile printing with TRAPIS for a greener tomorrow

TRAPIS eliminates fabric type restrictions. Unlike traditional methods, it delivers vibrant designs on all fabric types – from cotton to polyester, natural to synthetic. Moreover, TRAPIS reduces waste water by up to 90% and cuts the carbon footprint by up to 92% compared to traditional methods.

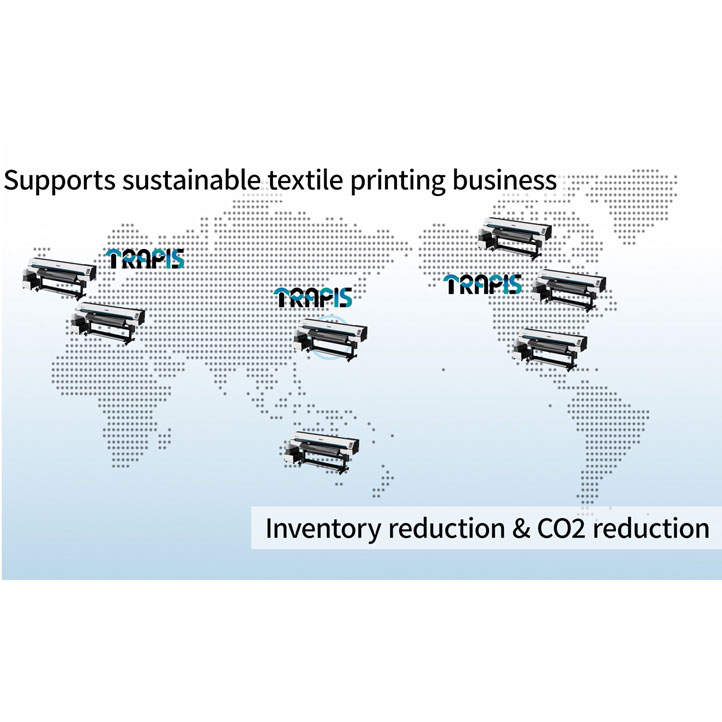

Due to its unparalleled flexibility, textile manufacturers can run dynamic production and deliver short runs in no time. TRAPIS is not only Ideal for eco-conscious businesses, it is also user-friendly and perfect for on-demand production.

Unique features

- Versatility

Print on any fabric for a wide range of applications, from apparel to home décor.TRAPIS can print on a wide range of fabrics, from natural fibers such as cotton and silk to synthetics such as polyester or nylon. As a result, this eliminates limitations for manufacturers and designers.

Print on any fabric for a wide range of applications, from apparel to home décor.TRAPIS can print on a wide range of fabrics, from natural fibers such as cotton and silk to synthetics such as polyester or nylon. As a result, this eliminates limitations for manufacturers and designers.

- Sustainability

Eliminate water waste by 90% and reduce the environmental footprint.TRAPIS significantly reduces both water consumption (up to 90%) and the carbon footprint (up to 92%) compared to traditional methods.

Eliminate water waste by 90% and reduce the environmental footprint.TRAPIS significantly reduces both water consumption (up to 90%) and the carbon footprint (up to 92%) compared to traditional methods.

- Simplicity

Easy-to-use system reduces both training needs and operating costs.TRAPIS offers an easy-to-use system that eliminates the need for complex training, what makes it suitable for smaller production facilities or on-demand printing.

Easy-to-use system reduces both training needs and operating costs.TRAPIS offers an easy-to-use system that eliminates the need for complex training, what makes it suitable for smaller production facilities or on-demand printing.

- Flexibility

Print short runs or production on demand, minimising stock costs.The system is designed for both short and long runs, allowing manufacturers to quickly adapt to changing trends and minimize inventory.

Print short runs or production on demand, minimising stock costs.The system is designed for both short and long runs, allowing manufacturers to quickly adapt to changing trends and minimize inventory.

Tailored for versatile fabric applications

in diverse industries

TRAPIS offers textile producers the flexibility to print on all types of fabrics, both natural and synthetic fibers, including cotton, silk, polyester, and blends. As a result, this allows manufacturers to produce a wide range of applications with a single printing system.

FASHION

FASHION

HOME & INTERIOR DECOR

HOME & INTERIOR DECOR

HOME & INTERIOR DECOR

HOME & INTERIOR DECOR

TP410: Next generation textile pigment Ink

Vibrant Colours, Superior Fastness, Flexible Application

TP410 is a new generation textile pigment ink designed for printing on a wide range of fabrics using the innovative TRAPIS transfer technology.

TP410 has vibrant colours and exceptional light and wash fastness. Moreover, it offers textile manufacturers confidence and flexibility for premium applications without the constraints of expensive or complicated printing processes.

Furthermore, TP410 is available in a convenient 8-colour set packaged in 2-litre vacuum bags and meets the industry’s most stringent standards, including ZDHC3 level and bluesign® approval.

For even more confidence

our TP410 eco-friendly ink is bluesign® APPROVED and ZDHC MRSL Lv.3 certified

Mimaki TP410 ink is bluesign® APPROVED and ZDHC MRSL Lv.3 certified, meeting the highest sustainability standards. These certifications ensure responsible use of resources, minimal environmental impact and worker safety, paving the way for eco-friendly textile printing solutions.

This printer includes Mimaki Core Technologies that offer the best print quality, maximum productivity and reduced exposure to risks that can delay production. See below list of core technologies that are included in TRAPIS.

Productivity & Convenience

- Nozzle Check Unit (NCU), to detect missing nozzles

- Nozzle Recovery System (NRS), to replace missing nozzles

- Automatic Cleaning Function (ACF), to keep the print head clean

- Jam Sensor, to prevent head damage

- Mimaki Degassing Module (MDM), to remove air from the ink channel

- Uninterruptable Ink Supply System (UISS), for continuous production

Quality printing

- Mimaki Advanced Pass System 4 (MAPS), to reduce banding

- Waveform Control (WFC), for best possible image sharpness

- Variable Dot Technology (VDT), for smoother gradations

- Dot Adjustment System (DAS), for stable printing

Printer: Inkjet Printer

| Item | Printer |

| Sublimation Transfer Inkjet Printer TS330-1600 | Special firmware is required due to the use of dedicated ink |

| TRAPIS heater option (sold separately) | Optional heater attachment is required (sold separately) |

| Item | TS330-1600 FOR TRAPIS |

| Interface | Ethernet 1000 BASE-T (Recommend) / USB2.0 Hi-speed |

| Power Supply | Single-phase AC100-120 / 200-240V±10%, 50/60Hz±1Hz |

| Power Consumption | 2,880W or less |

| Dimensions (WxDxH) | 3.170 x 820 x 1.305 mm (124.8 x 32.3 x 51.4″) |

| Weight | 240 kg (529.1 lb) |

| Max heater temp | 60℃ |

Dedicated Ink: Highly safe ECO textile pigment ink

| Item | Ink |

| Textile Pigment Ink | The 8-colour set expresses a wide range of colours. Compared to conventional textile pigment printing, it achieves the same colour reproduction with less ink usage. Excellent safety and environmental friendliness. |

Dedicated Transfer Paper: Pigment transfer paper

| Item | Paper |

| Pigment transfer paper | Dedicated transfer paper with a special coating on its surface for textile pigment ink transfer. Prints efficiently with less ink usage. ECO-PASSPORT certification is planned, it has proven to be highly safe and can be used for a variety of textile application. |

Dedicated Transfer Machine: Transfer machine

| Item | Transfer machine |

| Higher pressure transfer machine for pigment transfer | Please contact Mimaki’s sales office or distributors for compatible manufacturer and product models. |

Software RIP

Software RIP designed for digital textile production.

TxLink5 Lite

TP410

Textile pigment ink

TP410 textile pigment ink, designed for the TRAPIS transferring system, offers a wide colour range with 8 colorus. It achieves equal colour reproduction using less ink compared to conventional textile pigment printing, ensuring excellent light and washing fastness.